| Windmill Cables | |||

| EPR/HFXLEVA LSOH 0.6/1kV Torsion Resistant Power Cable |

![]() Windmill Cables

Windmill Cables

Application

These halogen free cables with increased tolerance to torsion application, improved behaviour against abrasion and extended temperature, UV and ozone resistant are specially designed for wind turbines.

Standards

UL/CSA 22.2

UL 758

HD 22.13

Construction

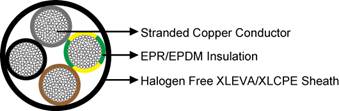

Conductor: Stranded annealed bare copper, class 5 according to DIN VDE 0295/HD 383/IEC 60228.

Insulation: Special thermoset EPR for high temperature. Special cross-linked improved for EI8 and EI7 base on EPDM can be offered upon request.

Sheath: Special halogen free thermoset XLEVA. High mechanical performance special cross-linked EM8 synthetic halogen free rubber based on CPE can be offered upon request.

Technical Data

Rated Voltage Uo/U (Um) |

CENELEC 450/750V; UL/CSA 600V |

Operating Temperatures |

-40℃~+90℃ |

Maximum Permissible Tensile Load |

15 N/mm² |

Minimum Bending Radius |

fixed: 4×OD; flexing: 6×OD |

Torsion Application |

+/-150°/m |

Short-circuit Temperature |

250℃ |

Flame Retardant |

IEC 60332-1/IEC 60332-3 |

Halogen Free |

IEC 60754 |

Smoke Density |

LSF EN 61034/IEC 61034 |

Oil Resistant |

Yes |

Ozone Resistant |

Yes |

UV Resistant |

Yes |

Water Resistant |

Yes |

Impact Resistant |

Yes |

Dimensions and Weight

Construction |

Nominal Overall Diameter |

Nominal Weight |

No. of cores×mm² |

mm |

kg/km |

1×25 |

13.5 |

371 |

1×35 |

15.0 |

482 |

1×50 |

18.7 |

730 |

1×70 |

19.3 |

888 |

1×95 |

23.0 |

1220 |

1×120 |

25.5 |

1540 |

1×150 |

28.8 |

1810 |

1×185 |

31.4 |

2210 |

1×240 |

33.8 |

2750 |

1×300 |

37.7 |

3520 |

1×400 |

41.4 |

4510 |

3×120 |

56.0 |

5200 |

3×150 |

61.5 |

6400 |

3×240 |

72.0 |

9780 |

3×25 |

30.0 |

1420 |

3×35 |

35.3 |

1850 |

3×50 |

39.8 |

2480 |

3×70 |

43.8 |

3180 |

3×95 |

49.0 |

4260 |

3×120 |

52.8 |

5490 |

4G25 |

32.8 |

1870 |

4G35 |

36.3 |

2320 |

4G50 |

42.5 |

3150 |

4G70 |

48.2 |

4240 |

4G95 |

53.5 |

5480 |

4G120 |

58.3 |

6950 |

G: with green-yellow earth core

×: without green-yellow earth core